Reciprocating Piston Air Compressors

ATCORP offers a versatile range of reciprocating piston air compressors, known for their robust durability, high-pressure capability, and dependable performance for intermittent and heavy-duty industrial applications.

- Oil Injected

- Oil Free

No products to display.

What is a Reciprocating Piston Air Compressor?

A Reciprocating Piston Air Compressor is the oldest, most common, and most versatile type of positive-displacement compressor. It utilizes a crankshaft-driven piston moving back and forth within a cylinder to mechanically draw in and compress air. Their robust, time-tested design makes them a highly durable and cost-effective solution, particularly for applications requiring high pressure or intermittent air supply. ATCORP’s range of piston compressors is built for reliability, easy maintenance, and long-term value across various workshop and industrial settings.

Key Features and Benefits:

- High-Pressure Output: Excellent at achieving higher pressures (up to 15 bar or more, especially with two-stage designs), making them ideal for specialized tools and processes like PET blowing and heavy-duty garage equipment.

- Simple, Durable Construction: Comprised of robust components like pistons and cylinders, this uncomplicated design is known for its longevity and ability to withstand demanding, high-load start-and-stop operation.

- Low Initial Investment: Generally require a lower upfront capital cost compared to rotary screw models, offering a cost-effective entry point for small to medium air requirements.

- Easy Maintenance: Due to its well-known technology and accessible design, maintenance procedures are straightforward, and spare parts are readily available and affordable, reducing long-term service complexity.

- Versatile Operation: Available in both oil-lubricated models (for heavy-duty industrial use) and oil-free variants (for sensitive applications like dental and food production).

- Intermittent Efficiency: Ideal for applications where the air demand is not continuous, as they maintain high energy efficiency during cycles of rest and operation.

Why Choose ATCORP for Your Piston Compressor Needs?

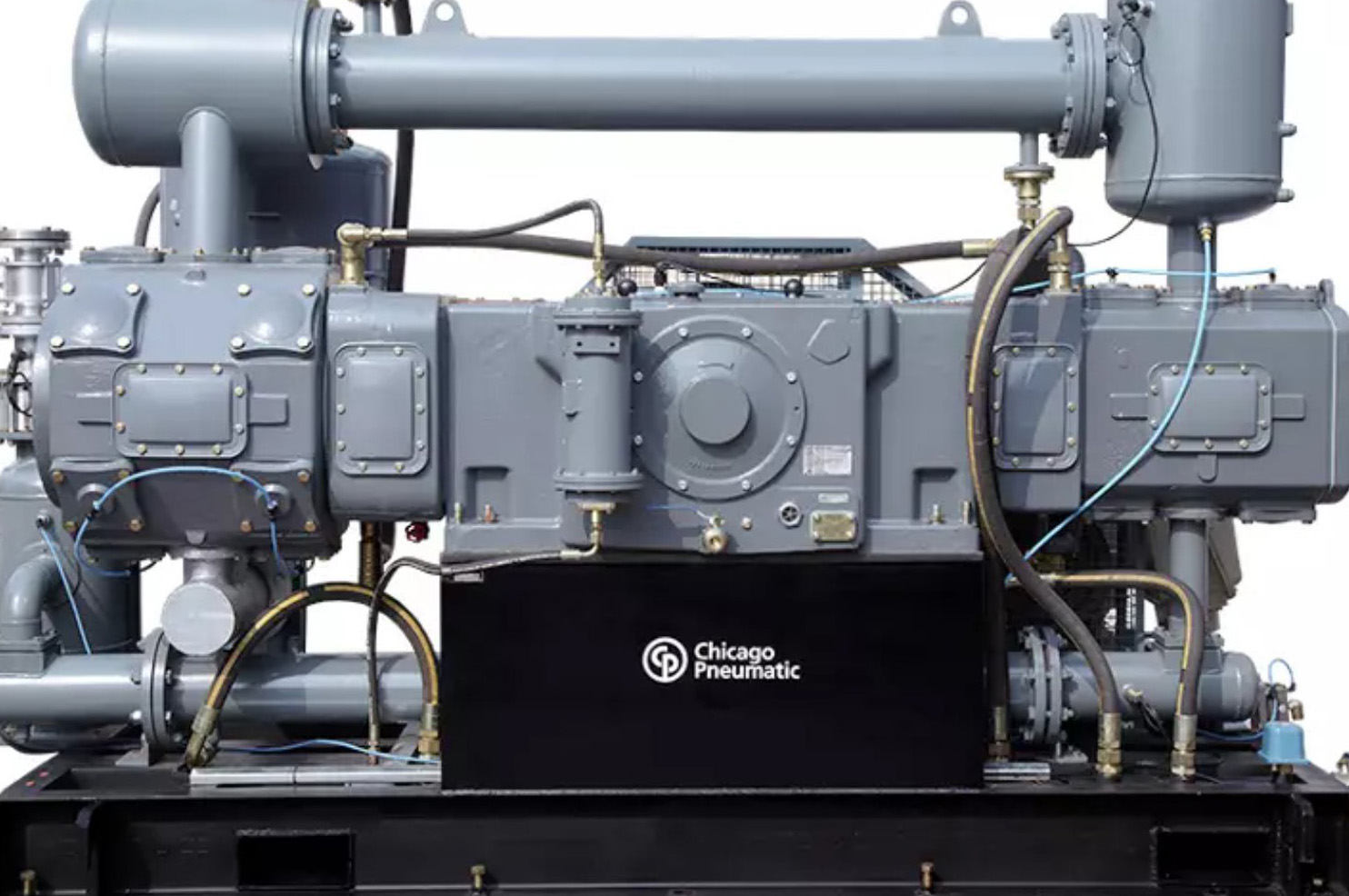

- Cutting-Edge Technology: Chicago Pneumatic compressors incorporate the latest advancements in reciprocating piston design for optimal performance and efficiency

- Reliability and Durability: Our compressors are built with high-quality components to ensure long-lasting and dependable operation

- Energy Savings: We offer energy-efficient models, including VSD options, to minimize your operating costs

- Expert Support and Service: Our dedicated team provides comprehensive support, from selection to installation and maintenance

- Customized Solutions: We can tailor solutions to meet your specific air demand and application requirements

Types of Piston Compressors Offered by ATCORP and Their Applications

ATCORP offers a variety of reciprocating piston compressor technologies to match different operational needs and efficiency requirements. Our range includes:

- Oil-Injected Reciprocating Piston Compressors: Reliable and robust, offering excellent performance for a wide range of applications

- Oil-Free Reciprocating Piston Compressors: Ideal for critical applications where air purity is paramount, such as in the food, beverage, pharmaceutical, and electronics industries

- Fixed Speed Compressors: A dependable solution for applications with consistent air demand

- Variable Speed Drive (VSD) Compressors: Intelligently adjust motor speed to match air demand, significantly improving energy efficiency and reducing operating costs

Powering a Wide Spectrum of Industries

ATCORP’s reciprocating piston air compressors are essential for a multitude of industrial processes, providing the consistent air power required by:

- Large-Scale Manufacturing Plants

- Automotive Assembly Lines

- Packaging and Processing Industries

- Textile Manufacturing

- Electronics Production

- Power Generation Facilities